Suitable for large and small potato chips, banana chips and other processing workshop, we can according to your workshop area, we provide a better solution to improve your production line equipment.

All Products

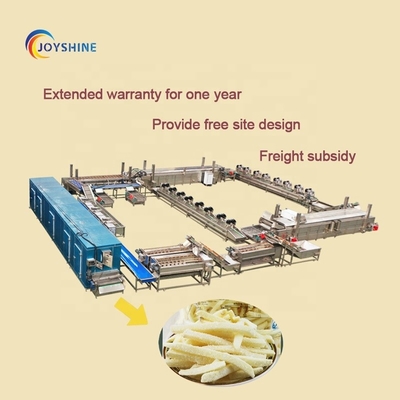

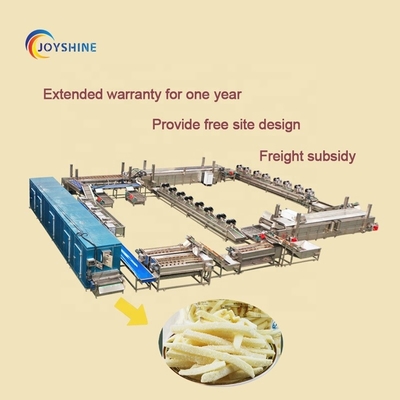

2 KG Joyshine Frozen Fries Processing Production Line for Golden French Fries Making

Product Details

| Condition | New | Applicable Industries | Food & Beverage Factory, Farms, Restaurant, Food Shop, Food & Beverage Shops |

|---|---|---|---|

| Showroom Location | None | Video Outgoing-inspection | Provided |

| Machinery Test Report | Provided | Marketing Type | New Product 2020 |

| Warranty Of Core Components | 1 Year | Core Components | PLC, Motor, Pump |

| Voltage | 380V | Power | 58 Kw |

| Dimension(L*W*H) | 8500*1100*1200mm | Weight | 2 KG |

| Warranty | 1 Year | Application Fields | Flour Mill, Seasoning Plant, Fruit Processing Plant, Snack Food Factory, Frozen Food Factory |

| Raw Material | Corn, Fruit, Wheat, Nuts, Soybean, Flour, Vegetables, Potato | Output Product Name | Potato Chips French Fries |

| Key Selling Points | High Productivity | Name | Electricity French Fry Production Line |

| Application | Snack Food Industry | Machinery Material | SUS304 |

| Final Products | French Fries, Potato Chips, Banana Chips | Heating Method | Electric Heating, Gas Heating |

| Type | Full Automatic | French Freis Size | 7-20mm |

| Potato Chips Thickness | 1-2mm | Banana Chips Thickness | 2-3mm |

| Package | Wooden Case Or In Nude | Port | Qingdao, Shanghai, Ningbo, Guangzhou, Etc. |

| Highlight | 2 kg frozen fries production line,joyshine french fries making machine,golden french fries processing equipment |

||

Product Description

Products Description

Joyshine Full-automatic Fried Potato Chips Production Line French Fries Making Machine Frozen Fries Processing Plant

1.Process capacity (finished output 100kg/h to 2000kg/h) and work flow can be customized.

2. All equipment are made of SUS304, electrical apparatus element are Schneider brand or CHINT brand.

3. Heating method: Electric heating, Gas heating or Diesel heating (equipped with Riello or Baltur burner), etc.

4. The size of french fries and the thickness of potato chips are adjustable.

5. For french fries line, we have special equipment to remove the unqualified fries.

6. With special designed fryer, quick heating and energy saving, enabled good performance.

No. | Machine Name | Function |

1 | Elevating Conveyor | For elevating and conveying fresh potatoes into the next washing peeling machine |

2 | Potato Washing Peeling Machine | Thoroughly washing and peeling the potatoes |

3 | Sorting Conveyor | For manually disposing the uncleaned places and selecting the defective potatoes |

4 | Chips Slicing Machine | Cutting the potatoes into chips, the thickness is adjustable |

5 | Bubble Washing Machine | Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch |

6 | Blanching Machine | Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the chips |

7 | Air Drying Machine | Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil jumped phenomenon |

8 | Elevating Conveyor | For elevating and conveying the fries into next fryer machine |

9 | Continuous Fryer | For chips frying |

10 | Vibrating Deoiling Machine | Through vibration to achieve deoiling purpose, and also to convey the fries uniformly to next machine |

11 | Pre-Cooling Machine | Through high pressure wind blowing to cool down the chips |

12 | Elevating Conveyor | For elevating the chips to next seasoning machine |

13 | Seasoning Machine | For seasoning the chips with different flavors |

14 | Packing Machine | For packing the finished potato chips |

Detailed Description

Fresh potato elevator

potato washing and peeling machine

Unqualified potato picking line

Potato cutter

For fries cutting For chips slicing

Potato chips washing machine

Blanching machine

Vibration de-water machine

Blowing line to remove the surface water

Elevator conveyortransport fries into the fryer

Continuous frying machine

Vibrating de-oil machine

Cooling machine to cool down the chips

Packing & Delivery

By express, air, railway and sea, LCL and full container.

About Us

We can provide the one-stop turnkey project with the industry-leading technology and R&D team as the front-end, the production and processing team led by more than 10 years of skilled workers the mid-end, quality inspection with near-rigorous standards, and the on-site installation by professional after-sales team.

Facility: 12 sets of shearing equipment, 48 sets of argon arc welding auxiliary equipment, shearing machine, cutting machine, electric welding machine, gantry crane, drilling equipment. Scale: workshop 15000㎡, 10 production lines.

We have more than 20 years of design and development team, 12 product patents and can be customized according to the needs of different customer

Certifications

Our company regularly participates in international mechanical equipment exhibition, let more customers understand the company's product information and quality service, and with Europe, Asia, South America and other regions and countries to develop long-term service and cooperation.

Our team is full of youth and passion for work, and we are capable of serving every customer well. Our company philosophy: to provide perfect product line, to provide every customer with quality service and long-term cooperation.

FAQ

What's the heating method: | Usually it can be electricity heating or gas heating. | ||||||

Material: | All machines adopt SUS 304 stainless steel. | ||||||

Date of delivery: | About 45 working days after receiving deposit. | ||||||

Voltage: | Customize according to the needs of different countries. | ||||||

Payment Tems: | T/T、Alibaba Trade assurance、L/C、WU、PayPal、Alipay、WeChatPay. | ||||||

Packing: | Exporting standard wooden case or full container. | ||||||

Transportation: | Shipping by express, air, railway and sea. | ||||||

Warranty: | 2 years | ||||||

OEM: | Customization of nameplate, material, slicing/cutting size, motor brand, packaging, etc. | ||||||

Recommended Products