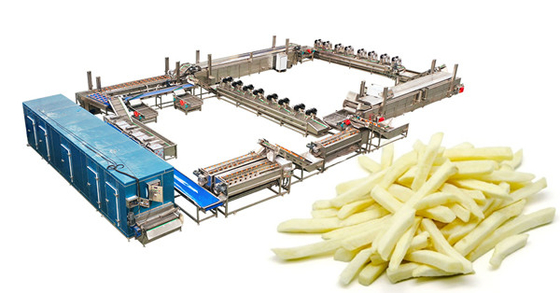

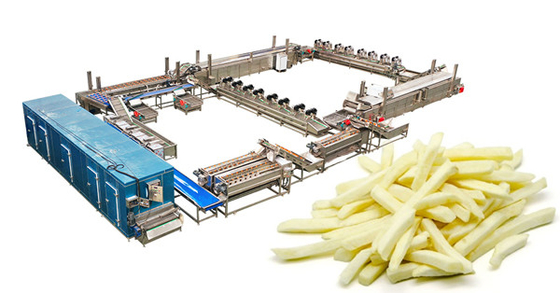

Fully Automatic French Fries & Potato Chips Production Line | High-Efficiency Industrial Food Processing Equipment

| Cutting Thickness | 2-10mm | Customization | Available |

|---|---|---|---|

| Finished Capacity | 100kg Per Hour | Specification | Customize |

| Type | Semi-Automatic | Blanching Temperature | 80-100℃ |

| Warranty | 1 Year | Style | Fully Automatic |

| Highlight | fully automatic french fries production line,industrial potato chips processing equipment,high-efficiency food processing machine |

||

Product Description:

The Joyshine French Fries Production Line is an advanced, fully automatic production system designed for large-scale processing of French fries, potato chips, and other fried snacks. With production capacities ranging from 100-5000kg/h, this line offers unparalleled flexibility and high efficiency, making it ideal for both small and large food processing

Features:

- Flexible Production Capacity: Designed to handle a wide range of capacities from 100kg/h to 5000kg/h, the production line can be scaled according to your specific production needs.

- Fully Automated System: Reduces the need for manual labor, streamlining the production process and ensuring consistent product quality and output.

- High-Quality Output: Whether you’re producing French fries, potato chips, or other fried snacks, this line ensures excellent texture and crispiness, meeting the demands of consumers.

- Customizable Settings: The line can be adjusted to produce different product sizes, with cutting thickness ranging from 2mm to 10mm, allowing you to meet diverse market preferences.

- Advanced Control Technology: Features an intelligent control system that simplifies operation, monitoring, and troubleshooting, ensuring smooth and efficient production.

- Durable Construction: Built with high-quality materials, the production line is designed to withstand the rigors of industrial food processing, ensuring long-lasting performance and reliability.

Technical Parameters:

| Attribute | Value |

|---|---|

| Type | Semi-Automatic |

| Finished Products | Potato Chips |

| Cutting Thickness | 2-10mm |

| Item | Industrial Potato Chips Fries |

| Warranty | 1 Year |

| Blanching Temperature | 80-100℃ |

| Machinery Test Report | Provided |

| Style | Fully Automatic |

| Automatic Grade | Automatic |

| Final Products | French Fries, Potato Chips, Banana Chips |

Other production lines available: Bread Crumb Production Line, Canned Vegetables Production Line, Fried Snack Production Line

Applications:

The Joyshine French Fries Production Line is perfect for businesses in the fast food, snack, and frozen foods industries. It can be used to produce various products, including French fries, potato chips, and other types of fried snacks, offering excellent versatility to meet the demands of different markets. Whether for large-scale production or small batch runs, the line ensures optimal performance and flexibility.

Why Choose Joyshine:

- Increased Efficiency: Fully automatic operation reduces labor costs and increases throughput, enhancing overall productivity and profitability.

- Tailored Solutions: We offer customization options for cutting thickness, production capacity, and other specifications, ensuring the line suits your unique business needs.

- Low Maintenance: Designed for easy maintenance and minimal downtime, the line is built to perform in demanding environments and can be serviced with minimal disruption to production.

Warranty & Support:

The Joyshine French Fries Production Line comes with a 1-year warranty and comprehensive after-sales support. Our team of technicians is available to assist with setup, maintenance, and troubleshooting, ensuring your equipment runs smoothly throughout its life cycle.

With a focus on reliability, efficiency, and customization, the Joyshine French Fries Production Line is the ideal solution for businesses looking to scale up their snack production capabilities while maintaining high product quality.