All Products

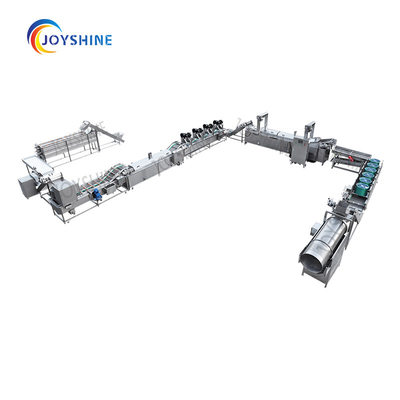

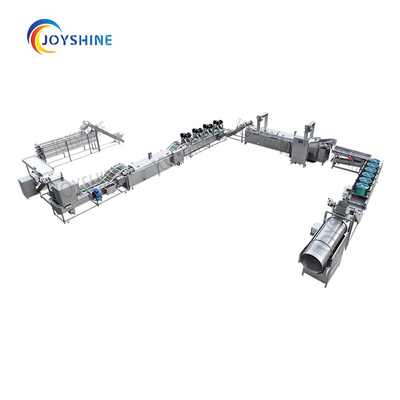

Advanced Full Line French Fries Peeling Cutting Blanching Machine for Seasoning Plant

Product Details

| Applicable Industries | Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction Works , Energy & Mining, Food & Beverage Shops, Advertising C | Showroom Location | None |

|---|---|---|---|

| Video Outgoing-inspection | Provided | Machinery Test Report | Provided |

| Marketing Type | Ordinary Product | Warranty Of Core Components | 1 Year |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor | Voltage | 220v, 380v |

| Power | 128 | Dimension(L*W*H) | Customized |

| Weight | 5500 KG | Warranty | 1 Year |

| Application Fields | Vegetable Processing Plant, Winery, Cannery, Flour Mill, Commercial Catering, Cooking Oil Factory, Meat Processing Plants, Seasoning Plant, Dairy Products Factory, Fruit Processing Plant, Bakery, Snack Food Factory, Frozen Food Factory, Beverage Factory | Machinery Function | Potato Production Line |

| Raw Material | Milk, Corn, Fruit, Wheat, Nuts, Soybean, Flour, Vegetables, Water | Output Product Name | Potato Production Line |

| Key Selling Points | High Productivity | Name | Potato Production Line |

| Custom | Can Be Accepted | Machine Material | Stainless Steel 304 Made |

| Application | French Fries Production Line, Chips | Usage | Washing Fruits & Vegetables |

| Capacity | 200/500/1000/2000kg/h | Package | Export Standard Wooden Packaging |

| After-sales Service Provided | Engineers Available To Service Machinery Overseas, Field Installation, Commissioning And Training | After Warranty Service | Video Technical Support, Online Support |

| Local Service Location | Viet Nam, None | Port | Qingdao Port, Tianjin Port, Shanghai Port, Guangzhou Port |

| Highlight | automatic french fries peeling machine,potato processing line with blanching,industrial french fries cutting machine |

||

Product Description

Products Description

We are professional direct manufacturer for potato chips or french fries making machines in China.

We have different solutions for different demands:

1: Different machines for making potato chips or french fries

2: Small, medium and large capacity from 30kg/h, 50kg/h, to 100kg/h, 300kg/h, to 1000kg/h, 2000kg/h output and workflow can be customized

3: Semi automatic or fully automatic processing machines

4: Electricity or gas, diesel heating source for blanching and frying machine.

5: The size of french fries and the thickness of potato chips are adjustable.

6: For french fries line, we have special equipment to remove the unqualified fries.

7: All machines are made of SUS304, Schneider electrical components and Siemens brand motor.

8: With special designed fryer, quick heating and energy saving, enabled good performance

Fully Automatic Frozen French Fries Production Process:

No. | Machine Name | Function |

1 | PVC Elevator | For elevating and conveying fresh potatoes into the next washing peeling machine |

2 | Potato Washing and Peeling Machine | Thoroughly washing and peeling the potatoes |

3 | Sorting Conveyor | For manually disposing the uncleaned places and selecting the defective potatoes |

4 | Fries Cutting Machine | Cutting the potatoes into fries, sizes adjustable from 7*7 to 12*12mm |

5 | Water Tank Elevator | water as buffer to prevent fries breakage, and simply removing starch, meanwhile elevating fries into next step |

6 | Fries Sorting Machine | Automatically picking up the small pieces fries |

7 | Bubble Washing Machine | Through high pressure waterflow and water bubbles to impact and scrub the fries to wash off the starch |

8 | Blanching Machine | Through 60-95 degree hot water blanching to inhibit the activity of the enzyme and maintains the original vivid color of the fries |

9 | Vibration Dewatering Machine | Through vibration to remove the surface water and also to transport the fries uniformly to the next machine |

10 | Air Drying Machine | Through high pressure wind blowing for pre-cooling and removing the excess water in short time, effectively prevent the fried oil jumped phenomenon |

11 | Elevating Conveyor | For elevating and conveying the fries into next fryer machine |

12 | Continuous Frying Machine | For quick frying the fries around 40 seconds in 180°oil to avoid the adhesion and extend the shelf life |

13 | Vibration Deoiling Machine | Through vibration to achieve deoiling purpose, and also to convey the fries uniformly to next machine |

14 | Pre-cooling Machine | Through high pressure wind blowing for pre-cooling and deoiling the fries |

15 | Freezing Machine | Through mechanical vibration and wind pressure, the fluidized quick freezer floats products on stainless steel mesh belt, frozen products and prevent adhesion, achieve IQF |

16 | Automatic Packing Machine | For packing the finished frozen french fries |

Detailed Description

PVC Elevator for Fresh Potatoes

Potato Washing Peeling Machine

Unqualitied Potato Sorting Conveyor

Potato Cutter

fries cutting chips slicing

Water Tank Elevator

Fries Sorting Machine

Bubble Washing Machine

Blanching Machine

Vibration Dewatering Machine

Air Drying Machine

Elevator Conveyor

Continuous Fryer Machine

Vibration Deoiling Machine

Air Cooling Machine

IQF Freezing Tunnel

Automatic Weighing and Packing Machine

Suitable for large and small potato chips, banana chips and other processing workshop, we can make suitable solution according to your workshop area and your real situation!

Related Products

FAQ

Company Profile

Recommended Products