All Products

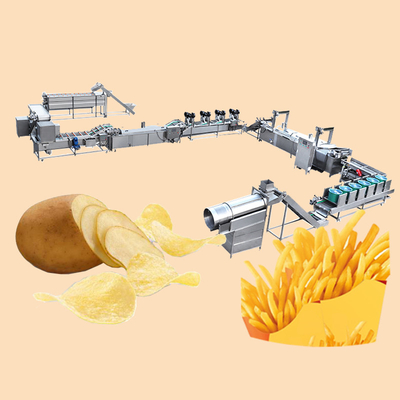

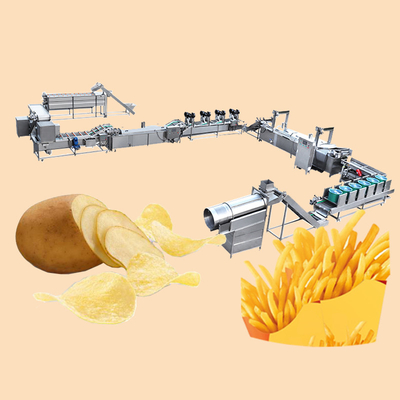

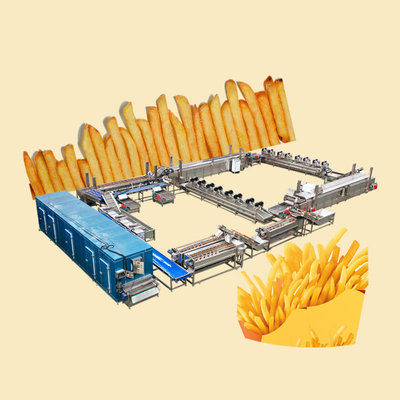

Snack Food Production Line Convenience with Finger Frozen French Fries Making Machine

| Place of Origin | Henan, China |

|---|---|

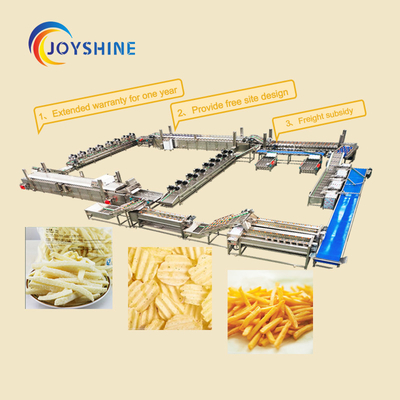

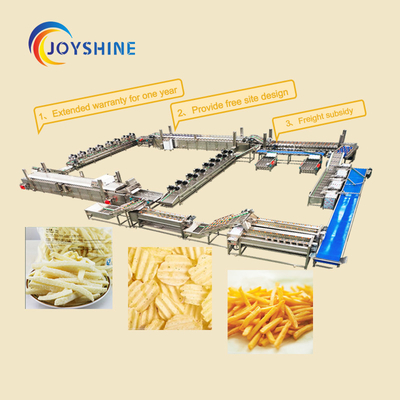

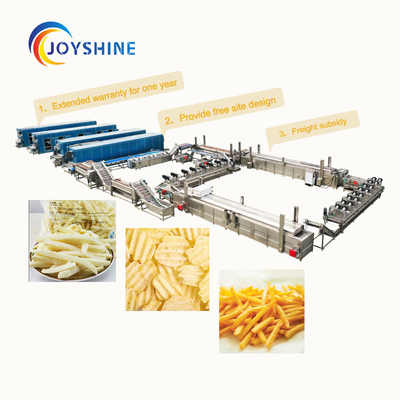

| Brand Name | JOYSHINE |

| Price | $14,800.00/sets 1-1 sets |

| Packaging Details | For Small Scale Potato Chips Finger Frozen French Fries Making Machine Production Line <br>1.Our company usually packs in standard export wooden case . <br>2. Shipping, train, express or upon clients' demands. |

| Supply Ability | 20 Set/Sets per Month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Condition | New | Applicable Industries | Hotels, Food & Beverage Factory, Restaurant, Home Use, Food Shop, Food & Beverage Shops |

|---|---|---|---|

| Showroom Location | Russia | Video Outgoing-inspection | Provided |

| Machinery Test Report | Provided | Marketing Type | New Product 2020 |

| Warranty Of Core Components | 1 Year | Core Components | PLC |

| Voltage | 220V/380V | Power | 10KW |

| Dimension(L*W*H) | 5500*2000*2000mm | Weight | 200 KG |

| Warranty | 1 Year | Application Fields | Vegetable Processing Plant, Commercial Catering, Fruit Processing Plant, Frozen Food Factory |

| Machinery Function | Potato Chips French Fries Making Production Line | Raw Material | Fruit, Vegetables, Water |

| Output Product Name | Finger Frozen French Fries Making Machine | Key Selling Points | High Productivity |

| Product Name | Potato Crisps Production Line | Type | Fully Automatic Processing Line |

| Capacity | 100kg/h | Feature | High Efficiency Potato Chips Line |

| Item | Industrial Potatos Chips Fries | Application | Snack Food Production Line |

| Accessory | Oil Tank And Extra Oil | Heating Type | Gas Or Electric |

| Function | Making Fresh Potato Chips | Usage | Food Industry Equipment |

| Port | Shanghai, Qingdao | ||

| Highlight | frozen french fries making machine,snack food production line,finger french fries production line |

||

Product Description

Products Description

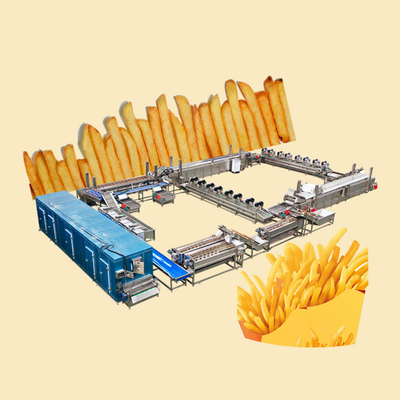

Frozen French Fries Production Line

This set of production line is a new type of french fries production line developed and developed by our company. This production line is made of high quality 304 Stainless Steel. PLC electrical control, high technical content, safe and efficient, the bearings are imported stainless steel bearings, electrical appliances. The use of imported brand-name products the technical level of domestic leading.

Detailed Images

Washing And Peeling Machine

1.Brush and corundurm rollers to peel the potatoes throughly.

2.Spraying system to clean the potatoes.

3.Spiral design to make sure automatic discharging.

The Picking Line

1.Manually pick up the defective potatoes.

2.Conveying speed adjustable.

Potato Chips Cutting Machine

1.Cut the potatoes into chips.

2.High efficiency, easy to operate.

3.Cutting surface is smooth without damege.

Bubble Washing Machine

1.Remove the starch from the potato chips.

2.Strong water flow, bubble impact.

3.High pressure spraying system.

4.Filter system and water recycling system.

The Blanching Machine

1.Inhbits enzyme activity.

2.Color protection of the potato chips.

3.Make the chips 70%-80% ripening.

The Air Drying Machine

1.Used after blanching for drying the surface of the blanched chips, get ready for next step frying.

2.Also used after frying for pre-cooling and de-oiling the fried chips keep the good teste.

The Frying Machine

1.Automatic lifting system, easy to clean.

2.Double mesh blet transmission to avoid the chips floating.

3.Oil filter and recycling system to automatically and continuously filter the oil residue to extend the service life.

4.Electric or gas heating.

Axial Air Dryer

1.Used after frying for pre-cooling and de-oiling the fried chips keep the good teste.

The Seasoning Machine

1.With spice tank, the flow of spice adjustable.

2.Rotary drum style and octangle style available.

Equipment Composition

Equipment Composition

Why Choose Us

About Us

We can provide the one-stop turnkey project with the industry-leading technology and R&D team as the front-end, the production and processing team led by more than 10 years of skilled workers the mid-end, quality inspection with near-rigorous standards, and the on-site installation by professional after-sales team.

Facility: 12 sets of shearing equipment, 48 sets of argon arc welding auxiliary equipment, shearing machine, cutting machine, electric welding machine, gantry crane, drilling equipment. Scale: workshop 15000㎡, 10 production lines.

We have more than 20 years of design and development team, 12 product patents and can be customized according to the needs of different customer

Our company's productivity can meet the stock of spot products. One of the independent warehouses has an area of more than 2000 square meters, and we can quickly supply customers with machine sets, for production lines.

Certifications

Our company regularly participates in international mechanical equipment exhibition, let more customers understand the company's product information and quality service, and with Europe, Asia, South America and other regions and countries to develop long-term service and cooperation.

Our team is full of youth and passion for work, and we are capable of serving every customer well. Our company philosophy: to provide perfect product line, to provide every customer with quality service and long-term cooperation.

FAQ

What's the applicable materials: | Root vegetables or fruits. | ||||||

Serving life of blades: | 1-2 years | ||||||

Date of delivery: | 5-7 working days | ||||||

Voltage: | Customize according to the needs of different countries. | ||||||

Payment Tems: | T/T、Alibaba Trade assurance、L/C、WU、PayPal、Alipay、WeChatPay. | ||||||

Packing: | Exporting standard fumigation wooden box. | ||||||

Transportation: | Shipping by express, air, railway and sea. | ||||||

Warranty: | 2 years | ||||||

OEM: | Customization of nameplate, material, slicing/cutting size, motor brand, packaging, etc. | ||||||

Recommended Products